Mold making is a versatile craft that bridges the distance between artistry and manufacturing. It includes developing specific replicas of unique devices or fashions using various mold substances consisting of silicone rubber, urethane rubber, and plaster. This method allows artists, designers, and manufacturers to produce more than one copy of problematic designs regularly.

The popularity of mold-making has grown significantly across numerous industries and pursuits. Artists and sculptors use molds to breed their creations for exhibitions and income, making sure consistency in each piece. Mold making is essential for prototyping and mass production of complicated parts and components. Moreover, hobbyists and DIY fanatics include mold makers for crafting personalized presents, cosplay accessories, and replicas of favored items.

The Purpose and Importance of Making Molds

In manufacturing and numerous crafts, the procedure of mold-making plays a critical role in creating particular and replicable forms. Whether in industrial production, art, or culinary arts, molds function as foundational gear that enables the replication of shapes and paperwork with accuracy and performance. This article explores the numerous functions and importance of making molds across distinct fields, highlighting their function in innovation, manufacturing, and creativity.

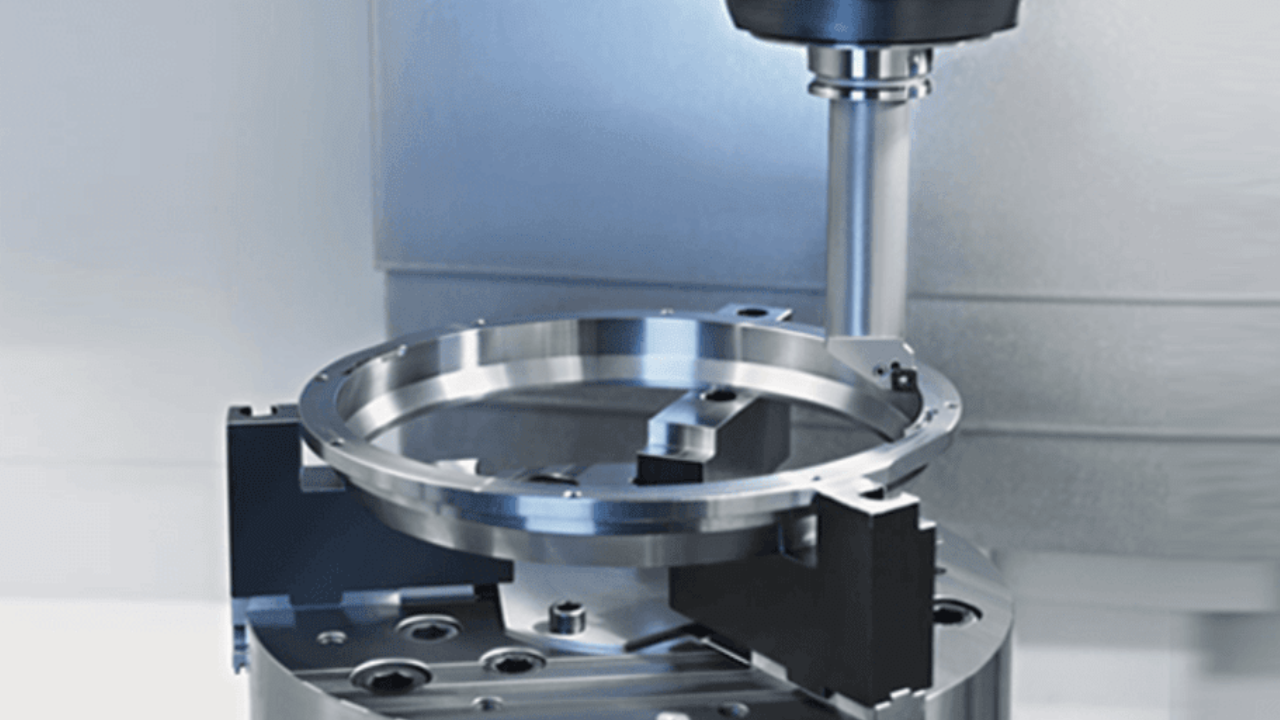

Industrial Applications

In commercial manufacturing, molds are crucial for mass-generating intricate additives and products. Industries such as automobile, aerospace, and electronics rely closely on molds to form materials like metallic, plastic, and composite materials. The primary cause right here is to acquire consistency and precision within the production procedure. Molds ensure that each component manufactured adheres to specific specifications, lowering variability and improving best management measures.

Artistic and Creative Uses

Beyond industrial applications, molds are integral to creative endeavors. Artists and craftsmen use molds to copy sculptures, pottery, and other artistic paperwork. This method allows artists to create more than one copy of their original paintings, facilitating broader distribution and accessibility. For instance, in ceramics, molds permit potters to supply identical pieces efficiently, keeping the integrity of their designs at the same time as the assembly marketplace needs. In sculpture, molds offer a method to breed difficult information that could be hard to achieve manually.

Culinary Innovations

In the culinary world, molds serve both realistic and aesthetic functions. Cooks and pastry artists utilize molds to shape food into appealing forms that decorate presentation. From chocolate pralines to complicated cake decorations, molds enable cooks to achieve uniformity and precision in their culinary creations. Additionally, molds are hired for the manufacturing of mass-market food gadgets, including sweets and confectioneries, to ensure consistent length and form across batches.

Medical and Dental Applications

Mold-making reveals important programs in the scientific and dental fields, especially within the fabrication of prosthetics, implants, and dental appliances. Prosthetic appendages and orthotic contraptions are specially designed, utilizing molds to suit the patient's necessities as they ought to be. When making dental crowns, bridges, and dentures that precisely fit the patient's oral anatomy, molds, also known as impressions, are taken. The use of molds in those disciplines not only improves patient consolation and capability but also ensures the toughness and effectiveness of scientific interventions.

Architectural and Construction Uses

In architecture and creation, molds are pivotal in creating decorative factors and constructing additives. Concrete molds are employed to form architectural functions that include columns, balusters, and facades. Through the use of molds, architects, and developers can reap complicated designs and textures that enhance the aesthetic enchantment of systems. Moreover, molds permit the prefabrication of production factors off-web, thereby accelerating the building process and reducing on-site hard work requirements.

Innovations and Prototyping

Revolutionary industries, along with product layout and era development, depend upon molds for prototyping and iterative testing. Engineers and designers use molds to create prototypes of recent products and additives quickly and successfully. These prototypes permit the assessment of form, match, and characteristics earlier than finalizing designs for mass manufacturing. Through the use of molds within the prototyping section, organizations can mitigate dangers and refine their products based totally on remarks and checking out outcomes.

Sum Up

The purpose of making molds spans a wide array of industries and disciplines, each profiting from the precision, efficiency, and flexibility that molds provide. Molds function as vital equipment for shaping materials and creating uniform, replicable forms. As industries evolve and innovate, the role of molds continues to expand, riding development and facilitating the conclusion of modern thought across diverse fields.